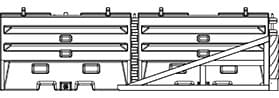

Each SLED module is manufactured from a high visibility yellow polyethylene that is UV stabilized to minimize degradation. It is designed to deform and rupture on impact, absorbing the energy of the errant vehicle. SLED has the most versatile transition for shielding all permanent and temporary portable barriers. The combination of hinging and contouring, allows the transition panels of the SLED End Treatment to be attached to narrow, wide or other profile shapes with either converging, or diverging angles, up to 10 degrees.

SLED Sentry Longitudinal Energy Dissipater

*Please Call Us for a Quote on this Product*

SLED™

The Sentry Longitudinal Energy Dissipater (SLED) is a narrow, non-redirective gating crash cushion that is designed to shield permanent and temporary barriers including concrete, steel, and plastic. The four internal steel cables of the SLED envelop the impacting vehicle, reducing potential secondary accidents.

Municipalities & Contractors Sign-in for Special Pricing and Tax Rates

CompareDescription

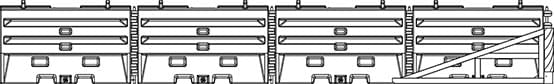

TL-1 Specifications

- Weight

- Empty 675 lbs.

- Filled 2,505 lbs.

- Length

- 12′ 7″

- Width

- 22 ½”

- Height

- 42″

- Speed Rating

- 31 mph

TL-2 Specifications

- Weight

- Empty 835 lbs.

- Filled 4,505 lbs.

- Length

- 18′ 11″

- Width

- 22 ½”

- Height

- 42″

- Speed Rating

- 45 mph

TL-3 Specifications

- Weight

- Empty 995 lbs.

- Filled 6,505 lbs.

- Length

- 25′ 3″

- Width

- 22 ½”

- Height

- 42″

- Speed Rating

- 62 mph

Features

- FHWA Accepted for Shielding the Blunt End of Concrete, Steel and Water Filled Barriers

- Quick and Easy Set-Up, No Foundation Anchoring, Minimized Installation Exposure Time

- Cost Effective End Treatment for Concrete, Steel or Water Filled Barriers

- Universal Transition Quickly and Easily Attaches to a Variety of Barrier Shapes and Sizes

- SLED’s Stout Design Virtually Eliminates Vaulting

- Narrow Footprint is Ideal for Work Zones or Roads with Minimal Shoulder Spacing

- Shortest Length TL-3 Water Filled Crash Cushion, Fewer Incidental Impacts

- Containment Impact SLED Minimizes Debris Field

- Visual “Drive By” Fill Indicators Quickly Verify Water Module’s are Properly Filled

- FHWA Accepted for Use in Uni- and Bi- Directional Applications

- Internal Steel Cables Help Envelop Vehicle After an Impact, Creating a Truly “Limited Gating” System